Grasping In-Mold Decorations: Methods, Trends, and Best Practices for Optimal Results

In the world of manufacturing, the art of in-mold decorations stands as a pivotal element of product style and manufacturing. As industries continuously look for cutting-edge means to boost aesthetic charm and performance, grasping the details of in-mold decorations has actually become an essential ability. From choosing the ideal products to incorporating sophisticated layout fads, the trip towards accomplishing ideal results in this domain name is complex. By diving right into the strategies, patterns, and finest practices that underpin effective in-mold design processes, businesses can unlock a realm of opportunities that not just boost the visual allure of their items but also simplify production effectiveness and bolster consumer interaction.

Material Choice

Product choice is a crucial facet of grasping in-mold decors, as it directly influences the high quality and resilience of the last product. When selecting materials for in-mold designs, it is essential to take into consideration aspects such as compatibility with the molding procedure, the desired visual outcome, and the environmental problems the product will certainly encounter.

In addition, products with high heat resistance are preferred for in-mold decorations, particularly for products that will be subjected to elevated temperatures during their lifecycle. By meticulously picking the suitable material for in-mold designs, producers can improve the overall top quality and longevity of their items, fulfilling the assumptions of both customers and end-users - In-Mold Decorations.

Style Advancement

A necessary consider advancing the field of in-mold decorations is the continuous expedition and execution of style advancement methods. Design technology plays a critical duty in improving the aesthetic appeal, capability, and general high quality of products manufactured making use of in-mold design processes. By incorporating cutting-edge layout aspects, manufacturers can separate their products out there, attract customers, and stay ahead of rivals.

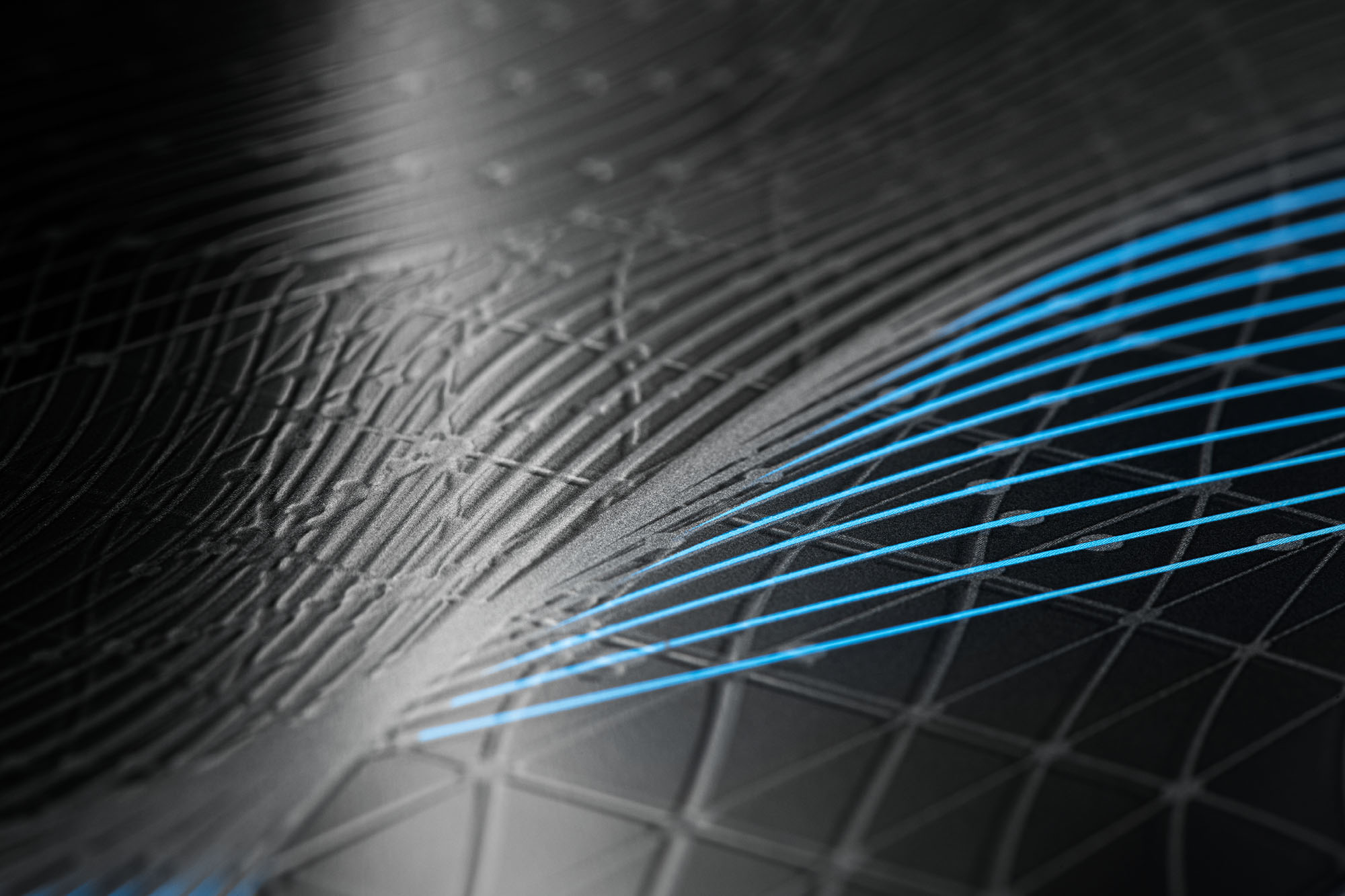

One of the vital elements of design advancement in in-mold designs is the assimilation of complex patterns, textures, and graphics that were formerly challenging to attain with conventional decor techniques. Advanced technologies such as 3D printing and electronic design tools enable designers to develop complicated and detailed styles that can be seamlessly transferred onto shaped parts. In addition, using vivid colors, metal coatings, and special results like gloss or matte textures can additionally boost the visual allure of in-mold embellished products.

Moreover, layout development expands beyond appearances to encompass practical enhancements such as ergonomic forms, incorporated functions, and customizable components that cater to particular customer needs. By welcoming design technology, producers can open new opportunities for creativity, personalization, and item differentiation in the affordable landscape of in-mold decors.

Manufacturing Efficiency

Efficient manufacturing processes are important for translating the cutting-edge layouts established in the field of in-mold decors right into top quality finished items that satisfy market demands and customer expectations. In the realm of in-mold decors, production performance incorporates different vital elements that contribute to the total success of the manufacturing procedure.

Furthermore, executing automation and robotics in the assembly line can substantially improve performance by improving recurring tasks and reducing the margin of mistake. Automation not only increases the production process however also boosts precision and repeatability, bring about a much more uniform and high-grade final product. In addition, taking on lean production principles, such as just-in-time inventory monitoring and waste decrease approaches, can additionally enhance production performance by reducing downtime and maximizing resource usage. Overall, an alternative strategy to manufacturing efficiency is vital in making best use of the potential of in-mold decor techniques and accomplishing ideal lead to the open market landscape.

Top Quality Control Steps

What are the essential methods for ensuring stringent quality assurance steps in the realm of in-mold decors? Quality assurance actions are extremely important in in-mold decor procedures to make certain the manufacturing of top notch and perfect ended up items. One vital approach is the execution of strenuous inspection methods at every phase of the manufacturing process. This includes carrying out detailed aesthetic assessments, dimensional checks, and color consistency assessments to determine any type of variances or problems beforehand.

Utilizing sophisticated technologies such as automatic inspection systems can likewise boost the high quality control procedure by providing precise and reliable data for analysis. These systems can identify imperfections that may be missed out on by hand-operated evaluations, therefore improving overall product find this top quality and uniformity.

Routine training and growth programs for employees involved in the in-mold design procedure can additionally contribute to preserving high-grade standards. By informing team on ideal practices, quality expectations, and the value of focus to information, companies can foster a culture of high quality awareness throughout the company.

Customer Allure

To boost the bankability of in-mold decor items, catering and understanding to consumer choices play a vital role in determining their appeal and success. Customer allure in in-mold decors is affected by numerous variables, consisting of style aesthetics, color selections, durability, and overall functionality. Customers are significantly looking for customized and special products that reflect their individuality and design. Consequently, supplying modification choices such as individualized designs, color variants, and textural aspects can substantially improve the appeal of in-mold decoration items.

Conclusion

In-mold designs use a flexible and effective means to improve product looks. Grasping in-mold decorations requires an all natural technique that thinks about all aspects of the production procedure to guarantee success.

In the realm of production, the art of in-mold designs stands as site a critical aspect of item style and production. Layout technology plays an important role in boosting the aesthetic appeal, performance, and overall top quality of products manufactured making use of in-mold design procedures.One of the crucial aspects of style development in in-mold decors is the combination of detailed patterns, structures, and graphics that were formerly challenging to attain with standard decor techniques.Reliable production procedures are important for converting the innovative layouts developed in the area of in-mold decors into high-grade completed items that meet market demands and customer assumptions. Providing customization choices such as tailored designs, shade variants, and textural elements can substantially boost the appeal of in-mold have a peek at this website design items.